DISCOVER THE

WORLD OF GRINDING

With the Real-Time-Analyser tiniest grinding details become visible in full brillance. It manages measuring tasks with high precision. A real asset for every precision-oriented grinding service.

BRILLIANT VISUALISATION

With the Real‐Time‐Analyser you make quality visible – otherwise very difficult to apprehend. Grinding quality does become visible, razor-sharp and rich in detail. With up to 200-fold magnification. Get yourself and your customers enthusiastic about it!

PRECISE MEASURING

We managed to combine the high-quality optics with a high-performance measuring software. By means of this perfect duo varied measuring possibilities are at your disposal. Whether angles, lengths or radii – the value is determined very quickly.

EASY OPERATION

Easy to operate, precise, reliable and 100% suitable for the workshop. With these central themes in mind we were designing the RTA. It will be your daily assistant at the grinding machine. Take advantage of our longstanding expertise.

SPECIALLY GEARED TO YOUR NEEDS

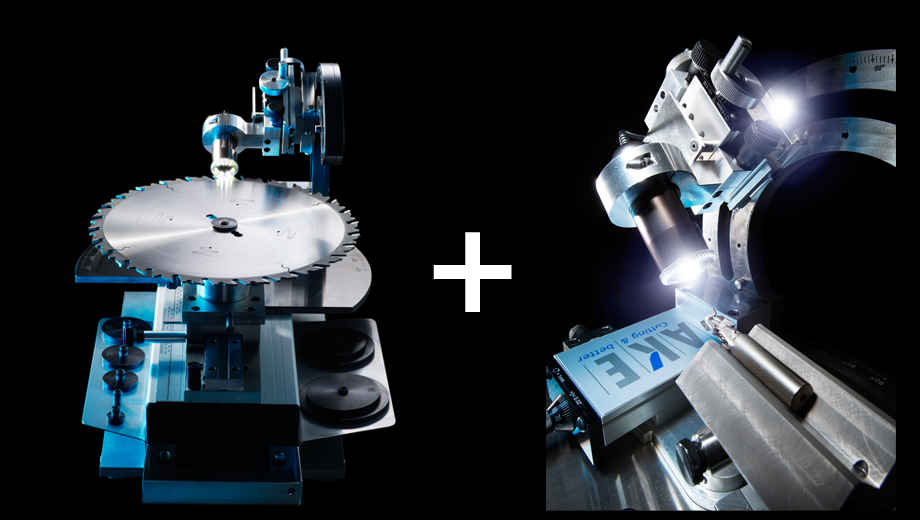

The RTA is modularly structured. Select the system that suits you individually. Depending on the design the RTA can be applied for checking circular saw blades, cutters, drill and others. With increasing requirements your RTA system will be joining in.

YOUR GRINDING QUALITY WILL BE GRASPABLE.

WITH THE RTA.

The Real-Time-Analyser (= RTA) is a system for professional tool visualisation coupled with a high-quality optical measuring unit.

It is a versatile all-rounder – designed for daily use at the grinding machine.

The RTA is precise, easy to operate, reliable and 100% suitable for your workshop. It is available at a very fair price.

HIGH-TECH FOR

YOUR ANALYSIS.

The RTA system is always equipped with a high-quality optic as well as high-performance visualisation and measuring software.

The features of the optics:

- High resolution for razor‐sharp and detailed images

- Incredible magnifying range (20x up to 200x, infinitely variable) for analyses to micro ranges

- Integrated glare filter for optimal illumination and contrasts

- Perfect images with all types of cutting material regardless of whether applied for carbide, HSS or diamond. A very special feature.

- Automatic magnification transfer for even faster measuring processes (available with the Advanced variant)

The features of the visualizing and measuring software:

- Measuring everything that the optics can capture:

Lengths, radii, diameters, circles, arches, angles - Subsequent measuring possible: Take a photo now, analyse later, as soon as time permits.

- Creating measuring logs

- Save, print, file. Can be sent by E-mail.

- Commentary feature

- Paste your text and comment the results and findings.

- Superimposing of images. Applied to check whether two images are congruent.

- Video feature

ANYWAY – WHAT

IS A GOOD

GRINDING RESULT?

It is very often the detail that determines which grinding quality is good – invisible to the naked eye.

With the RTA you will make quality visible. Examine your grinding result, compare yourself with competitors or enthuse your customer.

ADVANTAGES YOU CERTAINLY

DO NOT WANT TO GIVE UP.

You are a tool grinding service?

In that case the full functional range of the Real-Time-Analyser will benefit you.

These are some practical examples:

- Checking your grinding processes

- Safeguarding your own quality specifications

- Comparing your grinding quality with that of your competitors

- Visualising wear, breaks, cracks, edges and rounds

- Optical measuring and verifying angles

- Visual examination of soldering defects and discolouration

- Examining the dimensional accuracy in all planes

- Goods inward inspection, e.g. with grinding discs and tips

- Checking TOK and knives is possible

- Group discussion with colleagues, customers, suppliers

Apply the RTA for tool service, for the production of new tools, for controlling incoming goods and for increasing your productivity.

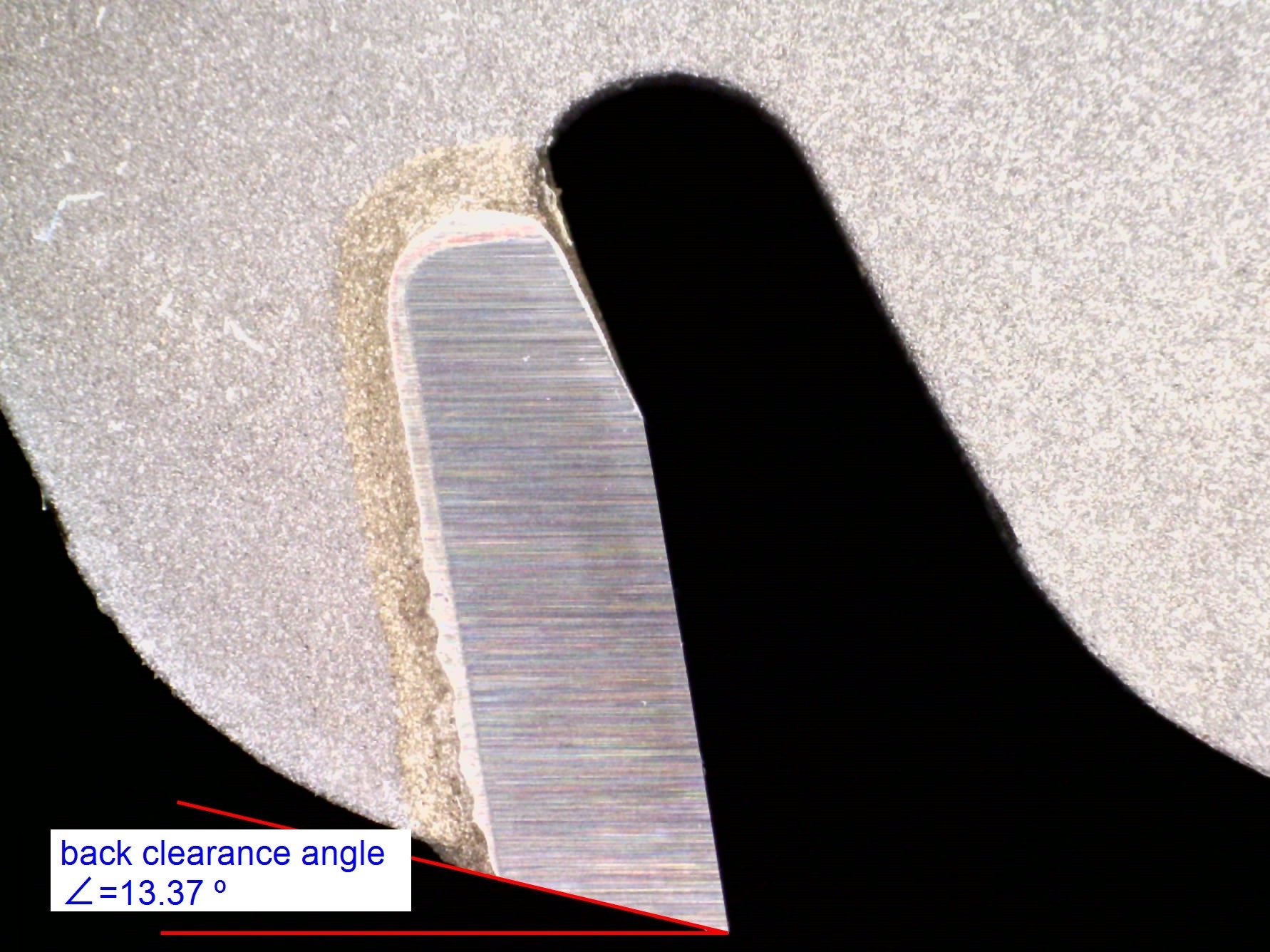

A NEW DIMENSION

OF GRINDING PRECISION.

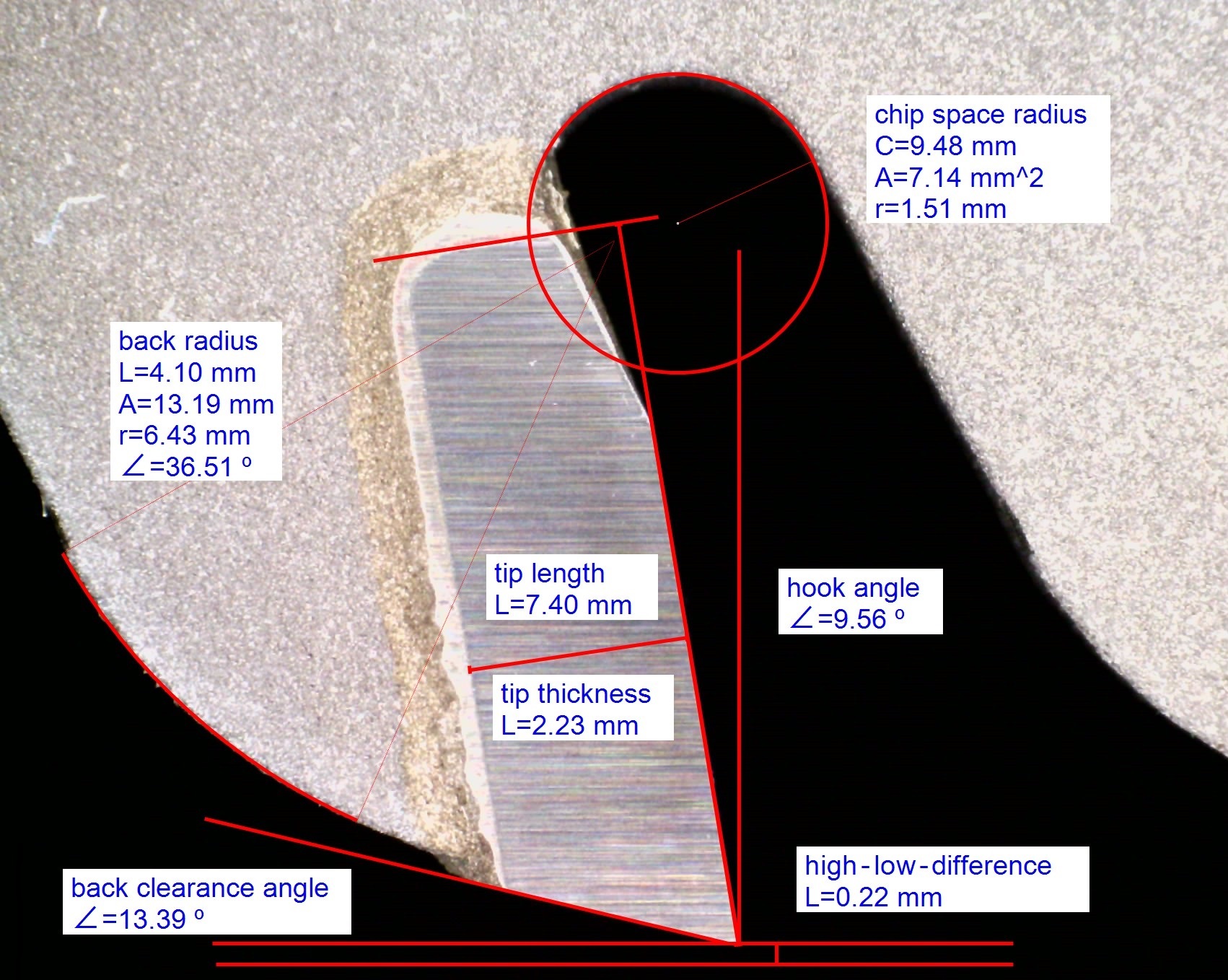

The RTA offers a variety of measuring possibilities.

Using the example of circular saw blade:

- Kerf

- Saw body thickness

- Angles

- Hook angle

- Back clearance angle

- Side clearance angle

- Tooth dimensions

- Tip height

- Tip thickness

- High-low-difference

- Off-centre grinding

- Bevels

- Width

- Length

- Offset

- Radii

- Fillets

- Gullet radii

ANSWERING YOUR

GRINDING QUESTIONS OF TODAY.

AND THOSE OF TOMORROW.

FROM PRACTICIONER TO PRACTICIONER.

The RTA had been developed by us: The company of AKE Knebel GmbH & Co.KG, based in the South German town of Balingen. We are manufacturer of quality tools, which are applied both in industry and crafts.

Initially the RTA had been developed for quality control in our own production.

Take advantage of a major tool manufacturer’s experience.

INDIVIDUALLY

TAILOR-MADE FOR YOUR WORK.

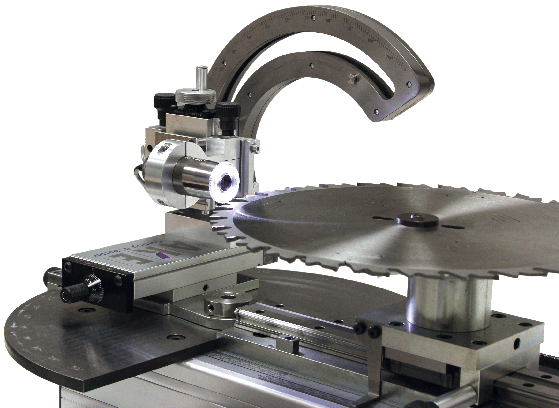

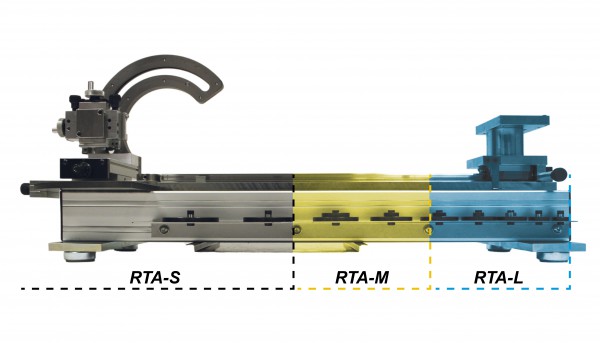

The Real-Time-Analyser is designed as a modular system. You can therefore select the very system specifically geared to your application requirements.

The length of the base frame is particularly important, if you want to analyse circular saw blades. The longer the base frame, the bigger is the maximum saw blade diameter with enough space on the RTA.

There are three Basic Systems to choose from:

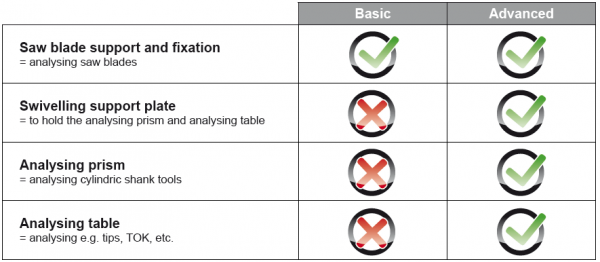

The RTA does not only differ in its basic systems (RTA-S, RTA-M, RTA-L) but also in its variants.

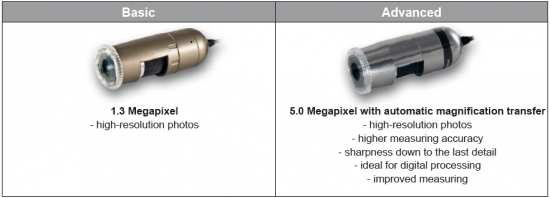

There are two RTA-variants – „Basic“ and „Advanced“. The variant already determines the optics included as standard and the accessories of the scope of delivery.

THE RTA BASIC.

OPTIMAL FOR CIRCULAR SAW BLADES.

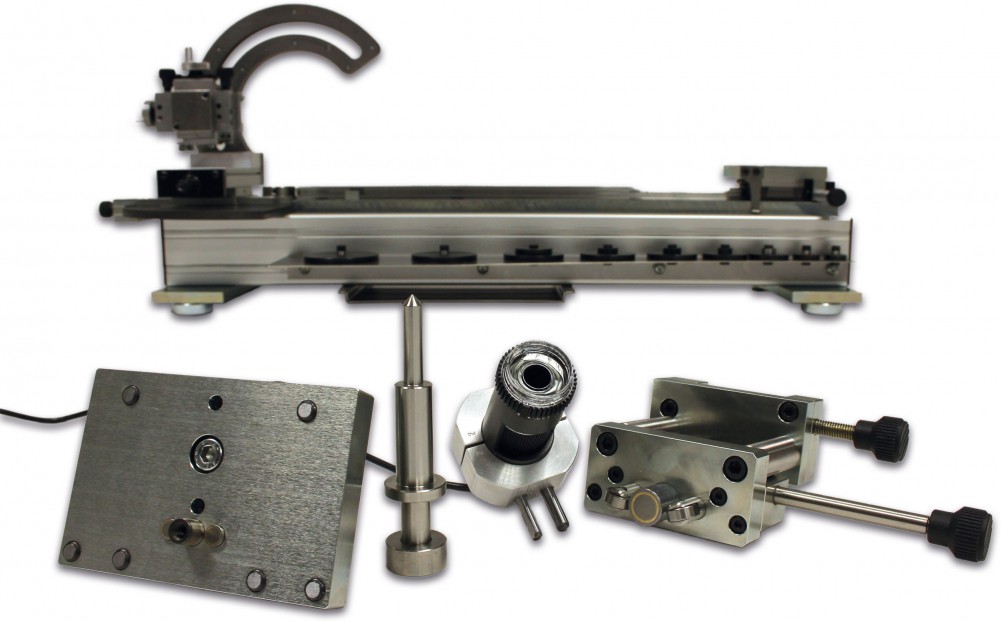

THE RTA BASIC IN DETAIL.

With the Basic variant saw blades can be analysed

with an image resolution of 1.3 MP.

The following accessories are included

in the scope of delivery (from left to right):

- Saw blade support

- Centring pin

- 1,3 MP optics mounted in the microscope holder

- Saw blade fixation

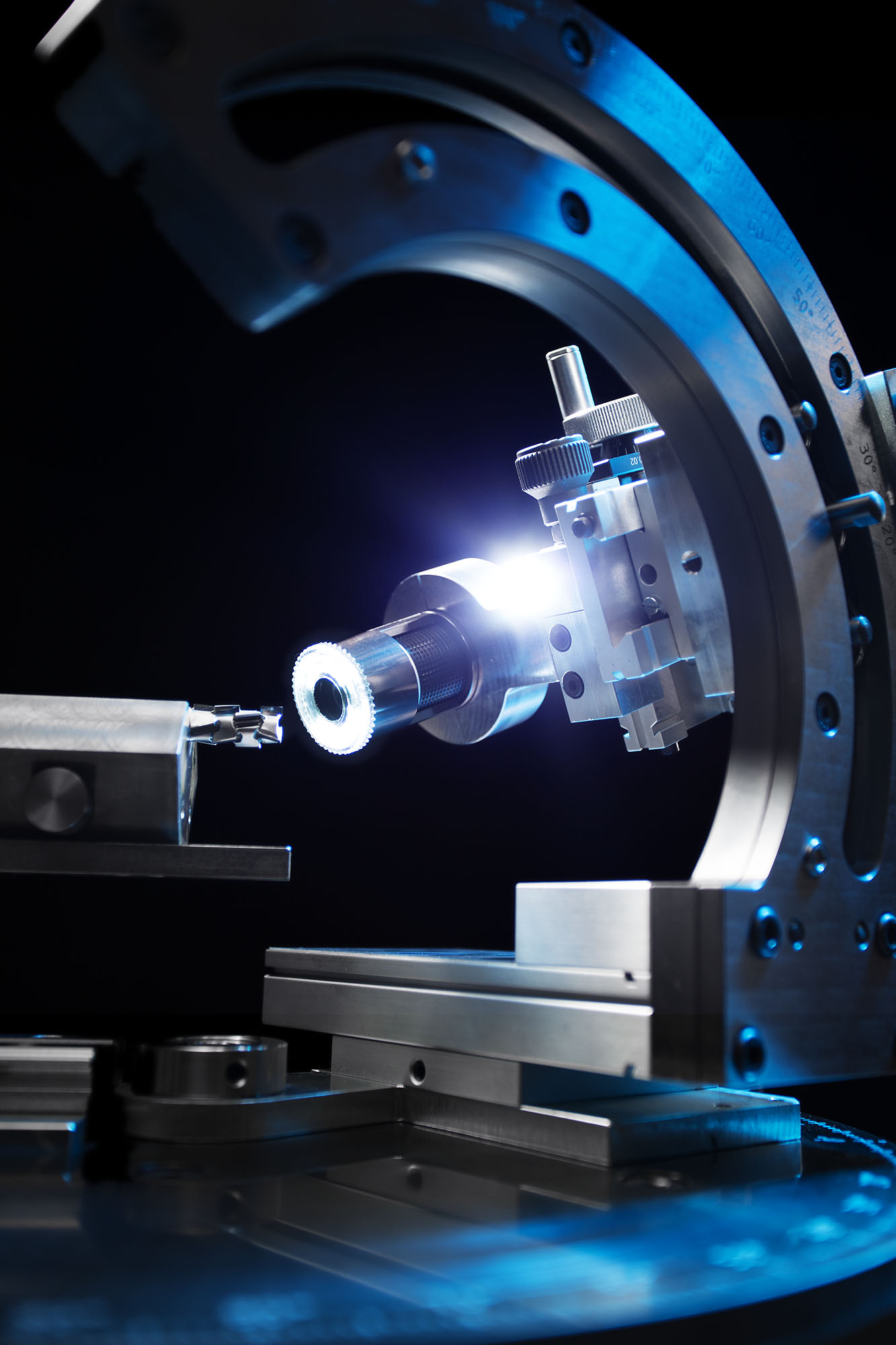

THE RTA ADVANCED.

FOR EVEN MORE POSSIBILITIES.

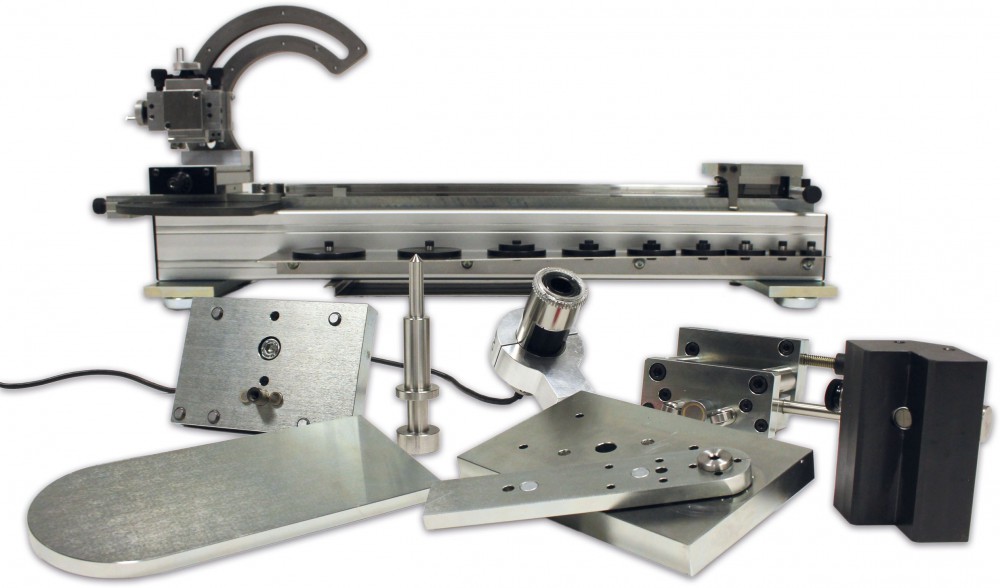

THE RTA ADVANCED IN DETAIL.

The Advanced variant offers the full range of functions of the RTA: Saw blades and cylindric shank tools (just like drills and cutters) can be put under the microscope. Moreover you can analyse everything that can be put on the supplied table. And all that with razor-sharp images with 5 MP resolution even with maximum magnification.

The following accessories are

included in the scope of delivery

(from left to right):

- Analysing table

- Saw blade support

- Centring pin

- Swivelling support plate

- 5.0 MP optics mounted in the microscope holder

- Saw blade fixation

- Analysing prism

INCREDIBLY

ATTRACTIVE PRICE.

With the Real‐Time‐Analyser you get a high-quality system at a very fair price.

The entry level price for the RTA-S in Germany is below 10,000.- EUR (net). The system thus enjoys a very attractive price-performance-ratio.

ARE YOU INTERESTED?

GO ON WITH A CLICK …

AKE Knebel GmbH & Co. KG | Hölzlestrasse 14 + 16 | 72336 Balingen, Germany

Phone: +49 7433 261-0 | info@ake.de